Home

Contents

Visual impact

Terrain impact

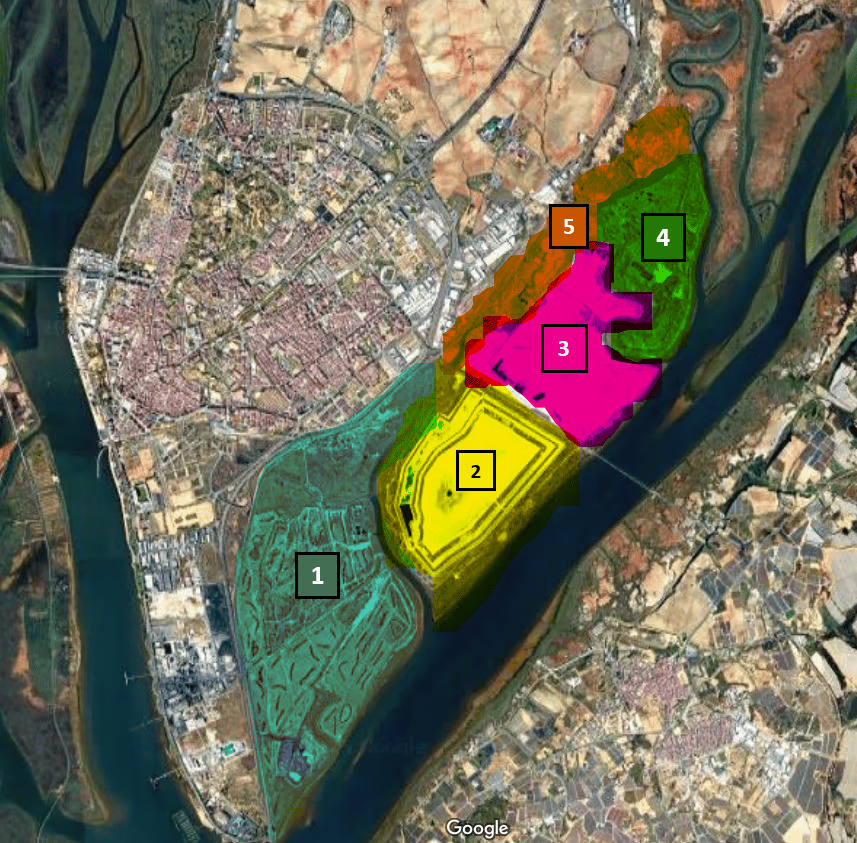

| Zone | Area (hectares) |

|---|---|

| Zone 1 | 400 |

| Zone 2 + Zone 3 | 441 |

| Zone 4 | 125 |

| Zone 5 | 0 |

Equivalent to

2471.054 acres

1000 hectares

10 square kilometers

90.91% of the city's surface

Knowing that Huelva city, with 143290 inhabitants in 2024, covers approximately 11 square kilometers.

Hydrogeological impact

Speech by Rafael Pérez López (PhD in Earth Sciences - Earth Sciences professor at University of Huelva | Dialnet)

The water inside behaves like an aquifer, meaning there is a flow that reaches the marsh bed.

Since the marsh is impermeable, when this flow reaches the marsh, it can no longer penetrate and begins to move sideways until it exits through the edges of the stack. These edge outlets are what carry the pollution from inside the stack to the estuary.

When the tide rises, the water from the estuary floods these secondary tidal channels. When the tide goes out, that water is discharged back into the estuary. What we see is that all these leaks, all these edge outlets that we recognize around the perimeter of the stack, are precisely water that enters through these secondary tidal channels, becomes contaminated, and then returns.

Conclusion

Our conclusion has always followed the same guideline: we must prevent water, the tide, from entering the stack.

How are zones being restored?

Zone 1

Covered with a 30-centimeter layer of natural soil and vegetation.

Zone 4

Covered with multiple layers (in ascending order): a 1-meter layer of building wastes, a 2-meter layer of theoretically inert industrial wastes, and more than 50 centimeters of topsoil.

How was phosphogypsum produced?

Between 1968 and 2010, in Huelva, this chemical reaction was used in five factories to produce phosphoric acid.

About 2.5 million tonnes of phosphogypsum were produced annually

About 100 million tonnes of phosphogypsum are stored in nearby stacks

What substances does phosphogypsum contain?

- More than 95% of gypsum.

- A high concentration of both radium-226 and thorium-230 radionuclides, which makes phosphogypsum considered a Naturally Ocurring Radioactive Material, NORM, in the European Union.

- 20% of the uranium and more than 95% of the lead and polonium present in the original phosphate rock.

- Remaining phosphoric acid trapped between its particles, which explains phosphogypsum high acidity (pH ≈ 2).

Phosphogypsum management systems

Cases in other places

Release into the sea

Phosphogypsum, mixed with water, forms gypsum slurry. This gypsum slurry, generally untreated, is dumped into seas or rivers. This management system is implemented in places like Gabès, Tunisia, where there has been devastating consequences on marine and terrestrial fauna and flora, and also in the health of the local coastal populations. Since 1989, this system has been forbidden in the United States, as it is required to store phosphogypsum in land stacks.

Storage in controlled deposits

Phosphogypsum is stacked in large land stacks. These stacks occupy a significant and ever-growing land area, and they require costly lifetime management in both their operational and post-operational states. This system requires experience and good environmental standards to protect ground water. As an example, the first generation of phosphoric acid industries in China lacked these features, causing significant groundwater pollution.

Case of Huelva

Until 1998

About 20% of the generated phosphogypsum was discharged into the Odiel River channel, while the remaining 80% was pumped in suspension with seawater into the stacks, where phosphogypsum was decanted, and the polluted acidic (pH ≈ 2) seawater (around 10 million meters cubed per year) was released into the Tinto River channel without any treatment.

From 1998 until the end of the production (31 December 2010)

Due to a change in the environmental policy according to the OSPAR convention, all the phosphogypsum was pumped with freshwater in a closed circuit and placed into the piles, ending Odiel and Tinto releases from the previous system.

Possible solutions to Huelva phosphogypsum

Transport

egmasa has studied a solution to transport the phosphogypsum dump with trucks. In summary, the transport solution is not feasible as it would require 485 26-ton trucks every working day for 30 years.

Can phosphogypsum be recycled and valorized?

The ugly PG duckling has turned into a swan. The long-incubated PG business case has hatched.

It took many years to make the phosphogypsum consumption business possible, and in essence, converting stacks into stocks

Thanks to scientific and engineering progress, phosphogypsum isn't a waste, but a high-potential material with many new applications being discovered

Phosphogypsum use cases

Roads

The following cases have demonstrated phosphogypsum road applications. No problems, failures, or other abnormalities have occurred so far.

- September 2016: a 200-meter-long, high-concentration water-stabilised phosphogypsum layer was laid on Wenjin Avenue in Wuhan.

- 2017: a 500-meter test section was built on the Wuyi Expressway in Yunnan.

- 2019: a 400-meter test section was built on the Jiuchang auxiliary road of the Yiwu Expressway.

- April 2019: Sichuan Lomon New Materials Co., Ltd. used improved phosphogypsum as roadbed filler for the construction of a test section on the approximately 200-meter connection line between the factory area and the extension line of Xinshi Industrial Avenue.

- September 2020: a 500-meter test section was laid on the Yao-Chu Expressway with a roadbed thickness of 39 centimeters.

Agriculture

The Institute of Geographic Sciences and Natural Resources of the Chinese Academy of Sciences has carried out a study under the title Effectiveness and Safety Evaluation of Phosphogypsum in Improving Saline-alkali Lands in Shandong, Hebei and Henan Provinces. The Da'an Alkaline Land Ecological Experimental Station of the Chinese Academy of Sciences used phosphogypsum to improve soda saline-alkali land. After repeated tests, it finally determined the most economical and efficient improvement sodic soil amendment material - phosphogypsum. The proposed "three benefit integration" model has been used in Da'an City, Zhenlai. It has been demonstrated and promoted in large areas in typical soda-saline-alkali areas such as Zhenlai County and Qian'an County. For plots with a yield of less than 100 kilograms per mu (1 mu = 667 square meters), after 3 to 5 years of "three benefit" treatments, by spreading acidic phosphogypsum and organic fertilisers, the yield per mu can reach more than 500 kilograms.

Polymer filling

Using phosphogypsum as raw material, it is calcinated at a high temperature to produce anhydrous gypsum (also called anhydrite), which has excellent performance as a cementing material or polymer filling material. Anhydrous gypsum can replace polymer fillers such as light calcium carbonate, light calcium, talc, barium sulphate, and other fillers for resin manhole covers, SPC floors, paints, coatings, biodegradable masks and other fields. Anhydrite does not contain harmful substances and is harmless to the human body and the environment. Applying it to polymer sheets for packaging can reduce dependence on petrochemical resources, reduce carbon emissions and energy consumption during the production process. At the same time, anhydrous gypsum has good recyclability and degradability, allowing polymer boards to be effectively processed and reused after being discarded, reducing the long-term burden on the environment.

Sulphuric acid

Guizhou Phosphate Group implements a large-scale phosphogypsum decomposition to produce sulphuric acid co-production cement clinker project, which can absorb 1.4 million tonnes of phosphogypsum (dry basis) and produce sulphuric acid. 650000 tonnes and 600000 tonnes of cement clinker (about 800000 tonnes of cement). It is the world's largest phosphogypsum decomposition to sulphuric acid co-production cement process device and a "smart" project that has been completed and put into operation. The sulphur extraction project uses phosphogypsum as a raw material and adds auxiliary materials such as silicon and aluminum for batching. After preheating, decomposition, and calcination, the generated sulphur dioxide flue gas is sent to the sulphuric acid plant to produce sulphuric acid and calcium oxide after recovering the heat. It is mineralised with silicon, iron, aluminum, etc. to form cement clinker.

Prayon

Prayon is a phosphate-based products company headquartered in Engis, Belgium, which has always applied circular economy principles for its phosphogypsum production

Central-Prayon Process

Prayon and Central Glass of Japan joined forces and developed Central-Prayon Process, consisting of the following stages:

- Parameters are optimized to produce high-quality phosphoric acid.

- Parameters are selected to produce high-quality "Alpha" Hemi-hydrate gypsum (α-HH).

- These stages reduce phosphorus pentoxide concentration from about 35% to less than 0.5%, producing at the end gypsum in the hemihydrate form (α-HH).

- A curing stage converts this hemihydrate gypsum (α-HH) into dihydrate gypsum (DH).

- Dihydrate gypsum (DH) is sold to cement companies and fertiliser companies.

CapturaCO2

CapturaCO2 is a FIC-Fighters member company composed of a multidisciplinary team of experts and researchers whose mission is valuing phosphogypsum as an input in profitable industrial processes that produce commercial products and even reduce emissions

Notable figures

Highlight Luis María Esquivias Fedriani (PhD in Physics - Condensed Matter Physics professor at University of Seville | Dialnet) and Alberto Santos Sánchez (PhD by Complutense University of Madrid - Researcher at University of Cadiz | Dialnet). They form part of the CapturaCO2 company and have also contributed to the development of CapturaCO2 patents.

Technology

CapturaCO2 is currently implementing two pilot plants to fulfill its mission: one pre-industrial and one industrial. Their technology, in the TRL scale, is now at TRL 6 (Technology demonstrated in relevant environment), and their mission is also to increase this TRL.

Patents

Pilot plants

Pre-industrial plant

The pre-industrial plant processes between 60 and 70 kilograms of phosphogypsum per day.

Industrial plant

The industrial plant processes between 60 and 70 kilograms of phosphogypsum per hour. As the plant operates 24/7/365, it has the capacity to process between 525.6 and 613.2 tonnes of phosphogypsum annually. This capacity will increase as long as CapturaCO2 technology improves.

University of Huelva

The Department of Earth Sciences and the Research Center on Natural Resources, Health, and the Environment of the University of Huelva have proposed a methodology which neutralizes the acidity and removes dissolved elements from phosphogypsum leachates

Products

This solution reaches removal percentages close to 100% for fluorine, iron, zinc, aluminum, chromium, uranium, copper, and cadmium. Moreover, the solids precipitated during the alkaline treatments contain the following elements of high economic interest:

- Rare earth elements

- Yttrium (353-3992 mg⁄kg)

- Scandium (21-164 mg⁄kg)

- Beryllium (5-7 mg⁄kg)

- Vanadium (1036-2974 mg⁄kg)

- Gallium (16-40 mg⁄kg)

- Uranium (721-2963 mg⁄kg)

Potential

It could lay the foundations for an effective and sustainable treatment system for acid leachates from phosphogypsum stacks. Furthermore, the costs related with the treatments could be covered by recovering the valuable elements contained in the newly-formed precipitates during the treatments.